in the event you’re within the cookware manufacturing enterprise, getting the best machines to optimize your manufacturing line is essential. whether or not you’re creating stainless-steel, aluminum, or composite cookware, choosing the correct wholesale Laser Blanking equipment can noticeably affect your output and merchandise good quality. With progress in laser slicing engineering, devices now present precision, velocity, and automation personalized to your advanced needs of cookware creation.

Table of contents:

critical specs to think about: energy, pace, and Accuracy

Assessing Compatibility with numerous Metals Used in Cookware

Boosting productiveness to Meet raising industry calls for

This guideline will walk you in the important technical specs, product compatibility, and productiveness Gains to contemplate when picking a Laser Blanking Machine, together with insights into top producers like JACKSON, recognized for their experience in cookware creation products.

vital technical specs to look at: electric power, pace, and precision

When picking a Laser Blanking device for your personal cookware line, prioritize energy, speed, and accuracy. Laser electricity decides the thickness of the metal you are able to Lower successfully, starting from 1.5KW to 6KW. superior-ability configurations are ideal for managing thicker metals like multi-layered composites, when lessen electric power options are enough for thinner resources like typical aluminum or stainless-steel. Speed is another crucial component, particularly if you aim to satisfy the here significant-volume demands of aggressive markets. search for slicing speeds of up to 30m/min for ideal productiveness. Most importantly, don’t compromise on precision. Machines with precision concentrations below 0.1mm make sure clean, burr-cost-free edges, doing away with the need For added ending procedures and maximizing the quality of your cookware products. JACKSON, a renowned Laser Blanking Machine manufacturer, offers devices equipped with cutting-edge laser tech, automated loading, and stacking functionalities, that are benchmarks of dependability and effectiveness while in the marketplace.

Assessing Compatibility with Various Metals Employed in Cookware

Cookware production typically necessitates flexibility, as various products use various elements such as stainless steel, copper, composite metal, and aluminum. be certain your chosen wholesale Laser Blanking Machine can take care of these metals across varying thicknesses successfully. As an example, JACKSON’s Laser Blanking devices support stainless-steel (0.three–2mm), copper (0.3–4mm), and aluminum (0.five–4mm), masking an array of generation demands. This adaptability is especially beneficial for suppliers making cookware with several levels, like tri-ply or multi-ply pans. Machines with Innovative laser technology, like Individuals built by JACKSON, enable specific cutting throughout these materials, making certain constant success whatever the steel form. Moreover, The graceful, burr-totally free edges supplied by laser slicing cut down the risk of waste and rework, bringing about better effectiveness inside your operations. By picking a device tailor-made to various metals, you’ll long term-evidence your manufacturing line even though retaining substantial-high-quality requirements.

Boosting productiveness to fulfill escalating sector requires

the worldwide cookware market continues to mature, driven by customer demand for prime-performing and sturdy kitchenware. To stay aggressive, brands have to Enhance productiveness without sacrificing good quality. A large-overall performance Laser Blanking device can be The main element to accomplishing this harmony. options which include automatic loading and uncoiling make these devices really autonomous, minimizing labor costs and improving upon operational effectiveness. Auto-stacking functionalities be certain that Slice sheets are neatly collected and arranged, lowering handbook managing and saving time. Also, contemporary Laser Blanking equipment, including Individuals made available from JACKSON, can Minimize any shape inside a diameter choice of 60–1000mm, enabling manufacturers to create intricate types that attract these days’s design and style-mindful consumers. the chance to deal with large volumes while protecting regularity positions your brand name to be a responsible decision during the competitive cookware marketplace. With JACKSON’s COOKWARE LINE laser alternatives, you may enrich efficiency, fulfill raising market needs, and elevate your cookware output to the subsequent stage.

buying the appropriate wholesale Laser Blanking Machine isn’t just a invest in; it’s a strategic go to boost performance, be certain significant-excellent output, and keep on being competitive inside the fast evolving cookware market. By analyzing essential requirements like electric power, speed, and precision, making certain compatibility with many metals, and focusing on productiveness-boosting capabilities, you could decide on a equipment that meets your company’s one of a kind demands. Renowned makers like JACKSON supply tailor-created remedies that cater for the demands of cookware creation, generating them a major option for companies aiming to enhance their creation traces. check out JACKSON’s Laser Blanking equipment choices these days and acquire the initial step toward transforming your cookware producing processes.

Jaleel White Then & Now!

Jaleel White Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Meadow Walker Then & Now!

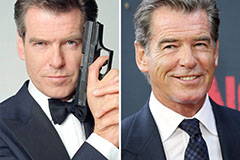

Meadow Walker Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!